Sorigin Recycling

Specialized in waste recycling machinery

Eddy Current Separator

Overview of Eddy Current Separator

Eddy Current Separator is suitable for crushed urban household waste, industrial waste, electronic waste, glass scrap, waste plastic doors and windows, urban wood waste, boiler bottom ash, a variety of metal mixtures, scrap car sliced copper, aluminum and other types of non-ferrous metal recovery and environmental protection industry material handling sorting.

Composition of Eddy Current Separator

The complete set of equipment consists of control and main body, the main part mainly includes rack, motor, cloth, sorting assembly (core components of equipment), permanent magnetic roller, conveyor belt, conveyor drive roller, gearbox, shield, etc.

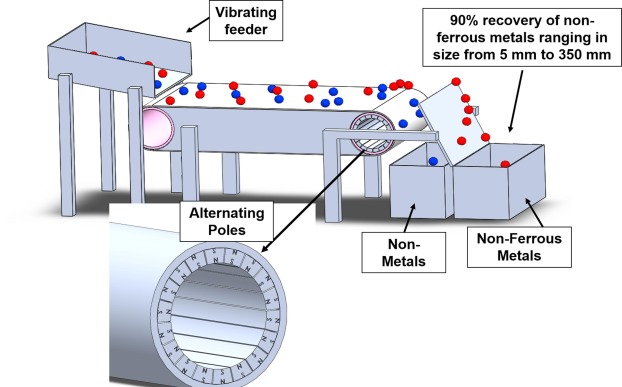

Working Process of Eddy Current Separator

Working Principle of Eddy Current Separator

The eddy current sorter is designed based on the principle that conductors to generate inductive current in a high-frequency alternating magnetic field.

When the machine works, it will produce a strong magnetic field with high frequency alternating on the surface of the sorting roller, when the conductive non-ferrous metal enters the magnetic field division, the vortex current will be induced inside the metal block, the vortex current itself will produce a magnetic field opposite to the direction of the original magnetic field, non-ferrous metal (such as copper, aluminum, etc.) will be due to the rejection of the magnetic field and leap forward along its transmission direction, to achieve separation from other non-metallic substances, to achieve the purpose of sub-selection; Its main area separation segment is based on the ratio value of material conductivity and density, and the high ratio value is easier to separate than the material with a low ratio.

Features of Eddy Current Separator

1) Easy to operate, automatic separation of metal from non-metallic, and reliable single-supply design make the system compact and reliable.

2) The separable metal particles have a large range, normally 3-100mm.

3) Easy to install, according to customer demand tailor-made, can be effectively connected with new and existing pipelines;

4) With stronger vortex currents, we developed more efficient sorters than traditional products using its unique magnetic application technology. Simple and flexible adjustment, you can achieve the best sorting effect;

5) The use of high gradient rare earth permanent magnet system, low energy consumption, easy maintenance;

6) According to the different steering of the rotor, different particle size materials can be sorted;

7) Many models choices(The width of the pallet is available from 300mm to 1500mm);

8) Variety rotor designs are available.

Specification of Eddy Current Separator

| Model | Belt width(mm) | Power(kw) | Capacity(m3/h) | Size(mm) | Weight(kg) |

| SY-400 | 400 | 3.7 | 1-2 | 2200x1600x1200 | 780 |

| SY-600 | 650 | 4.0 | 6 | 2250x1750x1075 | 1100 |

| SY-800 | 800 | 5.5 | 7.5 | 2360x1960x1110 | 1200 |

| SY-1000 | 1000 | 5.5 | 9 | 2470x2200x1140 | 1400 |

| SY-1200 | 1200 | 7.5 | 12 | 2560x2450x1180 | 1500 |

Leave Message

Leave your contact information and inquiry here to get a free quote!PRODUCT

- Mini Copper Wire Recycling Machine

- Scrap Copper Cable Wire Recycling Machine

- Scrap PCB Boards Recycling Machine

- PCB Dismantling Machine

- Aluminum Plastic Separation Machine

- Copper Aluminum Radiator Seprator

- Electrostatic Separator

- Eddy Current Separator

- Metal Crusher

- Air Gravity Separator

- Lithium-Ion Battery Recycling Plant

- Electromator Stator Seperator

Leave Message